Fixing

Screwing

MDF has good screw retention strength both in the faces and edges.

Screw types

Most types of screws can be used in MDF but the best results are obtained with two start, parallel thread screws. A high overall screw

diameter to core diameter ratio is desirable.

When fixing thin attachments to MDF, use screws which are threaded up to the head. Screws used for panel jointing or the fixing of thicker attachments may have a plain or threaded shank.

Screw position

The positions of screws inserted into the faces and edges of MDF should be decided in relation to board thickness and screw size. As a general rule, screws inserted into the face should not be less than 12 mm from the board edge and 25 mm from the corners. Screws inserted into the edges should not be less than 70 mm from the corners.

|

|

|

|

Pilot holes

Larger diameter pilot holes than those recommended for solid wood and particleboard are required in both faces and edges of MDF to accommodate the solid core of the screw. As a general rule, the pilot hole diameter should be 85 to 95% of the specified screw core diameter. This requirement is particularly important when screwing into the edges of thinner boards. Pilot holes should be drilled at least 1 mm beyond the expected depth of insertion of the screws into the board. A small counterbore is recommended to prevent any lifting of the MDF surface round the area of insertion of the screw.

Larger diameter pilot holes than those recommended for solid wood and particleboard are required in both faces and edges of MDF to accommodate the solid core of the screw. As a general rule, the pilot hole diameter should be 85 to 95% of the specified screw core diameter. This requirement is particularly important when screwing into the edges of thinner boards. Pilot holes should be drilled at least 1 mm beyond the expected depth of insertion of the screws into the board. A small counterbore is recommended to prevent any lifting of the MDF surface round the area of insertion of the screw.

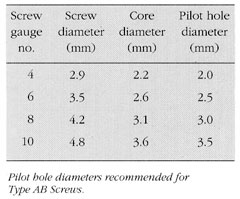

The pilot holes recommended when using ISO 1478/1983 Type AB screws are given in the Table. The drill diameters have been rounded off to the nearest 0.5 mm.

Withdrawal strengths

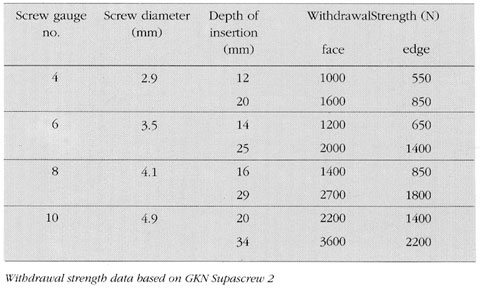

To illustrate the good holding power of screws in MDF, the forces required to withdraw typical two start parallel thread screws of different diameters in an axial direction from MDF faces and edges are given in the Table. The screws were inserted into the board to depths approximately equal to four times and seven times the screw diameters using the recommended pilot holes.

As a general rule, comparisons between the screw withdrawal strengths of different brands of MDF or MDF and other materials, are only valid if the same screw type and test method is used for each test.