Handling and Storing MDF

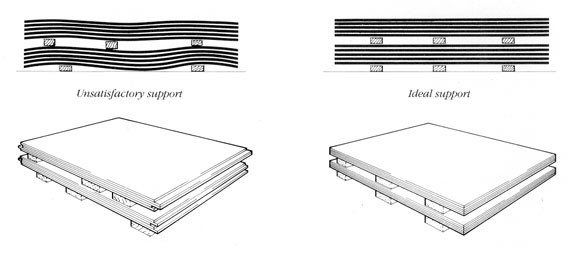

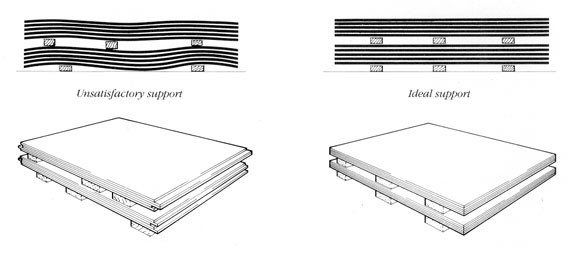

The different methods of manufacturing MDF with a uniform distribution of fibres throughout the thickness of the board ensure a balanced construction and potentially flat boards. The maintenance of this inherent flatness is however dependent upon the use of correct handling and storage procedures at all stages. Without these, boards may develop a permanent set under their own weight, particularly if they are not adequately supported on flat pallets or by sufficient bearers during any storage period.

The following procedures are recommended:

-

MDF sheets should preferably be stored horizontally and lifted clear of the floor using dry bearers as supports. Polythene sheeting should be laid on damp floors to prevent rising moisture.

-

Where individual bearers are used they should be of equal thickness and placed at not more than 800 mm centres for boards of 15 mm thickness and upwards, subject to a minimum of three bearers . Closer spacing, for instance 50 times board thickness, is recommended for thinner boards.

-

The bearers supporting successive layers should be in vertical alignment.

-

Stacks of boards should have flush sides to minimise damage to protruding edges or overhanging corners.

-

Vertical storage of small numbers of boards is acceptable provided the boards are well supported and placed in a close to vertical position.

-

The storage area should be well ventilated and the conditions should be reasonably dry. An average relative humidity of 50% rh will maintain board moisture content in the range 7 - 9%.

-

One or two scrap boards should be placed on top of stacked boards and panels as they progress through the factory or during any, prolonged storage period to eliminate any unbalancing effects of any short term changes in environmental conditions.