Interior Fitments

1. MDF in offices

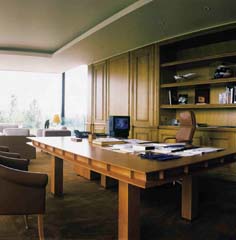

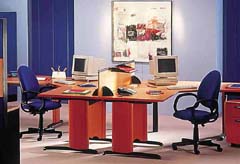

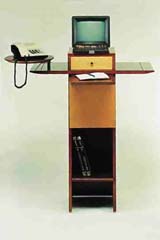

| MDF can be used effectively for the manufacture of general purpose units forming part of a comprehensive office system or for special units for executive offices or boardrooms. Commonly used finishes include wood veneer, plastics laminate, decorative foil and paint. A well proven range designed for relatively heavy duty use in local and national government offices includes fixed or moveable pedestal drawer units, filing cabinets, bookcases and linking units manufactured from MDF panels finished with acid catalysed or polyurethane paint in contrasting colours, sombre as appropriate to government offices or designer oriented in commercial offices. Desks and tables for this range are manufactured with powder coated metal frames supporting plastics laminate surfaced MDF tops, 25 mm thickness, with a post formed front edge, or, for lighter duty applications, 0.3 mm thickness PVC foil with a wrapped front edge. A benificial safety feature of this range is the rounding of the corners of the cabinet units and the shaping of the doors and drawer fronts with integral handle mouldings. The drawer boxes for this range are manufactured from 9 mm thickness MDF with finger jointed corners. Other offices ranges have been manufactured using the same general principles of construction but with slab end panels or pedestal supports manufactured from 25 mm thickness MDF. The screens used to separate the work areas in open plan offices can be manufactured from MDF. Lightweight screens can be manufactured with an MDF frame, typically 30 mm thickness enclosing an expanded honeycomb core and surfaced on each face with 3 mm thickness MDF skins. MDF can also be used for shaped landscape panels used to create informal divisions between work areas in an open plan office. The smooth and stable surfaces of MDF provide a good base for wood veneers. For this reason, MDF is first choice as a core material for executive and boardroom desks and tables which are often surfaced with exotic veneers including marquetry inlays and cross banded edges. Subject to a satisfactory underframe and support system in relation to the area of the table, the tops are normally manufactured from 25 mm thickness MDF, sometimes with a built up rim to increase stiffness and enhance the perceived quality. The ease of cutting special shapes, circles, ovals, half rounds and triangles and the facility of finishing the edges directly without the need for complicated solid wood lippings makes MDF a good choice for special application tables. The elimination of joint showthrough of wood lipped panels as a result of changes in ambient conditions is another good reason for using MDF, particularly where the wood veneers are finished with a high build, high gloss lacquer. Standard grade MDF is considered to be acceptable for the manufacture of most office furniture and fitments but the possibility of using a low formaldehyde grade should not be overlooked, particularly when fitting out large offices which have an air conditioning system with a limited input of fresh air. |

|